.jpg)

In today’s customer-driven design and manufacturing world, tolerances are ever-increasing as more and more functionality is being pressed into a shrinking product envelope. CAD models are now being annotated with more critical tolerances, beyond basic fit and clearance requirements, such as complex surface profiles. Since virtually all product development is now done in the CAD realm, the ensuing data and models are the perfect nominal standard to guide and inspect the entire manufacturing process.

The UG NX provides a solid edge and assists AutoCAD professionals to upgrade their career from it to get the opportunity to earn more. The UG NX or also known as SIEMENS NX is known as the future technology of the CAD/CAM environment. It provides advanced capabilities to design, draft, and work with engineering-related designs, and manufacturing. With such capabilities, the software has amazing future career prospects and helps the professional to attain good job opportunities from the market. So, if you are looking to develop your career in it you are in the correct place.

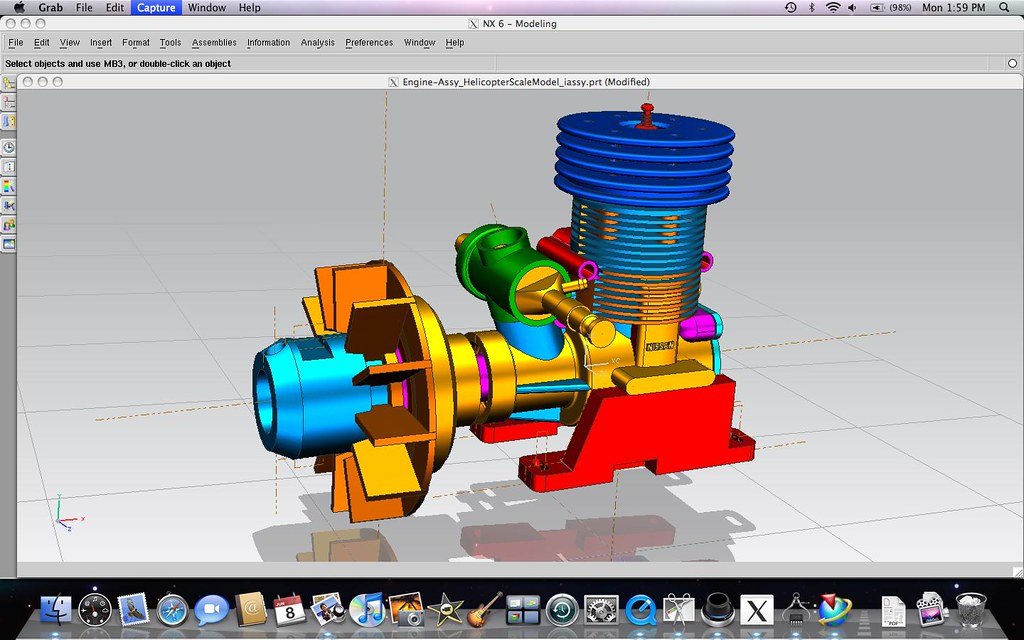

Unigraphics NX (also known as Siemens nx) is an advanced High-end CAD/CAM/CAE software package originally developed by UGS Corporation, but since 2007 it is owned by Siemens PLM Software. It is used, among other tasks, for Design, Engineering analysis, manufacturing finished design by using included machining modules.

This course designed in such a way that you will learn about all important tools and commands of the software. This is a streamlined course to take you from knowing nothing about NX to give you all the knowledge and skills needed to become a certified Siemens NX designer. This course should enable you to, with confidence, use NX to design your next innovation. After this course, you can proudly list your NX skills in your resume.

The UG-NX training is ideal for product designing and engineering enthusiast. As such there is no formal qualification or certification required to undergo this training.

The NX CAD is designed to advance the student and enhance their productivity curve. The course intends to increase the student’s skills, by teaching them essential course segments and accomplish the following:

Open and examine NX models

Create and edit basic assembly structures

Create and edit drawings

Use synchronous modeling

Create component patterns

Define revision identifier

Apply top-down assembly modeling

Manage assembly arrangements

Build your work performance consistent with all CAD/ CAM systems

Will easily manage and attain knowledge in the development of the complex products

Get proficiency in providing visual analytics to improve the decision making

Will easily read the data and get indulged in building up production of new products every year

Get the opportunity to attain the certificate in UG NX from the university to upgrade your profile and to earn more

All these benefits you see help you to attain big opportunities available for the UG NX professional. Some required eligibility criteria fall for those who have completed CAD basics and command over the process involved with mechanical engineering. These skills help in learning the course perfectly as well as help you to gain command over the UG NX quickly.

Essentials for NX Designers as the initial class, is designed to launch students on the path of productivity. This course is designed to meet the student’s expectation to transfer classroom instruction to productivity on the job. The Essentials for NX Designers course ignites the student through professional instruction pertaining to product model design, product model detailing, assembly modeling and the basics of the master model concept.

NX CAD (formerly Unigraphics) is a robust 3D solution that provides fast and realistic concept design and modeling. Superior in power and flexibility, NX CAD design tools are a breakthrough in the industry, setting new standards for speed performance and ease of use. Product design is about innovation.

NX CAD is an integrated solution that helps you develop innovative new products. With leading-edge design tools and technologies, NX streamlines and accelerates the product development process. Some key benefits include:

Manufacturing companies today are driven by increasing pressure to develop more innovative products in a shorter time frame than ever before. The first step in rethinking the business model surrounding product development is to transform the design process. Using NX CAD for 3D design, you can improve your overall performance.

Less re-design, fewer errors, and better quality

Evaluate design quality, projected cost, and manufacturability before physical prototyping

Capture knowledge and automation tools

Powerful 3D design capabilities including: Wireframe, surface, solid, and direct modeling

Freeform shape modeling, surface continuity, analysis, simulation, and visualization tools

Integration with other applications for simulation, tooling, and machining

Create quality and accurate rendered images faster and easier

The NX Sheet Metal Fundamentals class is designed to introduce users of Sheet Metal to basic modeling concepts inside of NX/Unigraphics then apply and understand the NX Sheet Metal tools and concepts. This course is designed to meet the student’s expectation to transfer classroom instruction to productivity on the job. The NX Sheet Metal Fundamentals course ignites the student through professional instruction pertaining to sheet metal model design, creating a flat pattern, and documenting in the drafting environment.

NX CAM Turning Manufacturing Process is the core turning class designed to convey concepts, functionality and application of the turning module. Turning Manufacturing Process is taught from the perspective of an NC/CNC programming session and emphasizes programming concepts and techniques which take advantage of the latest developments in turning equipment and technology.

NX CAM Fundamentals is designed to help students with CAM programming productivity as well as CAD modeling and assemblies for manufacturing. The NX CAM Fundamentals course will provide professional instruction pertaining to efficient 2 ½ and 3 axis milling CAM programming techniques. This introductory class introduces CAM programming and CAD modeling in the context of real-life scenarios and will include instructor-led demonstrations, follow along demonstrations and hands-on exercises.

NX CAM Advanced Techniques is designed to help students with complex CAM programming productivity. The NX CAM Advanced Techniques course will provide professional instruction pertaining to advanced 3 to 5 axis milling CAM programming techniques. This intermediate/advanced level class will focus on CAM programming in the context of real-life scenarios and will include instructor-led demonstrations, follow along demonstrations, and hands-on exercises.

NX provides a complete set of numerical control (NC) programming capabilities in a single CAM system as well as an integrated set of manufacturing software applications.

These powerful applications facilitate part modeling, tool design and inspection programming – all based on the proven, future-proof architecture of NX.

NX allows the use of a common 3D model from part design to production. Advanced model editing, tool and fixture design, part and inspection programming are all associative, enabling fast, easy changes.

NX CAM provides a wide range of functionality, from simple NC programming to high-speed cutting and multi-axis machining. Such advanced programming capabilities allow one system to address many tasks.

Productivity increases through the use of application-specific programming, such as the volume-based milling used for faster programming of prismatic parts.

Feature-based machining can reduce programming time as much as 90 percent.

Many typical programming processes can be streamlines through the use of wizards and templates.

NX CAM features a tightly integrated post-processing system.

Eliminate the need for separate simulation packages by using the integrated G-code-driven simulation.

Productivity is streamlined through the user’s ability to work on the system graphically. For example, by selecting and moving the 3D model of the tool to create a tool path you can drive the system quickly and intuitively.

All production begins with design engineering, where assemblies and component work pieces are conceived. Design data then are provided to manufacturing, where component work pieces are manufactured and products are assembled. ... Manufacturing engineering is where manufacturing processes are planned.

CAD |

CAM |

|

CAD refers to Computer Aided Design. |

CAM refers to Computer Aided Manufacturing. |

|

CAD is the use of computers for designing means computers are used to aid in creating the design, modifying and analyzing the designing activities. |

Computer Aided Manufacturing (CAM) is the use of computer software to control machine tools in the manufacturing of modules. CAM transforms engineering designs into end products. |

|

Computer Aided Design is also known as computer aided Drafting. |

Computer Aided Manufacturing is also known as computer aided Modeling. |

|

The purpose of CAD is making 2D technical drawings and 3D models. |

The purpose of CAM is using 3D models to design machining processes. |

|

Due to CAD it is much easier, more accurate and faster drafting, making 3D models impossible without Computers. |

Due to CAM atomization in machining process is achieved. |

|

So in Simple we can say CAD represents your part geometry to the computer. |

So in Simple we can say CAM converts the geometry to machine tool. |

|

For Computer Aided Design process only a computer and CAD Software are required for technician to create a design. |

For Computer Aided Manufacturing computer and often a CAM software package along with that for manufacturing process requires a CAM Machine. |

|

Computer Aided Design (CAD) software is mostly used by an engineer. |

Computer Aided Manufacturing (CAM) software is mostly used by a trained machinist. |

|

Some Examples of CAD software includes AutoCAD, Autodesk Inventor, CATIA, and Solidworks. |

Some examples of CAM software includes work NC, Siemens NX, Power MILL, and Solid CAM. |

Computer aided designing/drafting (CAD) and Computer-aided manufacturing (CAM) are closely related terms used where computers are involved in the design and manufacturing processes of a product in CNC industries.

Understanding UG NX is simple. It is easy to use interface software that provides a flexible and powerful interface with easy to use features. It is generally opted by big businesses such as manufacturing plants or any big engineering work related unit. It helps in designing the machines and tools or graphics that are used in modeling, machine operations, and designing. Today as the customer fragment is very broad due to digitalization. The UG NX, therefore, is gaining hype and many organizations are looking for experienced professionals who can handle the work with it.

In today’s competitive world, every student is trying to get a certification course which will make them eligible for a job. Students have various options available in the market now. They have CAD courses like CATIA, Nx CAD (UGNx) and CAE courses like ANSYS and Hyper works. BITOL Certified Design Engineer is one of such courses which will also help students to get a good job in Mechanical Design Domain.

According to a recent status from a leading job portal in India, there are about 35000 job posting who require Design Engineer. In India, The average salary of Design Engineer is about 4 Lakh, where with experience, the student can also have the package of about 10 Lakh. With increase of industrialization, the demand for design engineers will also grow in the future.

With the technological advancement, the parameters are always changing. So a design engineer has to also keep them updated to face and tackle every designing challenge. Design Engineers have to deliver quality designs in the required time frame. Thus this position requires great dedication and timeliness. You can put your creativity to test, every time you have a designing task assigned to you.

Most of the Mechanical or Automobile Engineering students prefer a desk job, especially Female engineers. If you have the same preference, Design Engineer is a savior for you. This is complete desk job, where the professional has to sit for long hours either creating designs or monitoring it.

Siemens ug-nx is a comprehensive CAD/CAE/CAM software guide; it can be utilized as a 3-dimensional modeling and design MCAD tool (either in direct modeling and parametric modelling), it can also be used in engineering analysis and simulation (electromagnetic studies, static/dynamic studies, and fluid studies). Finally, it can be used as a whole CAM solution.

Undergoing Siemens UG-NX Training is very useful for product developers, mechanical engineers, product designers and anyone working in the CAD/ CAE/ CAM business.

We hope that this blog post is helpful. Your inputs are highly appreciated.

Copyright Bitonlinelearn © 2021. All Rights Reserved | Design and Developed By BITINFOTECH