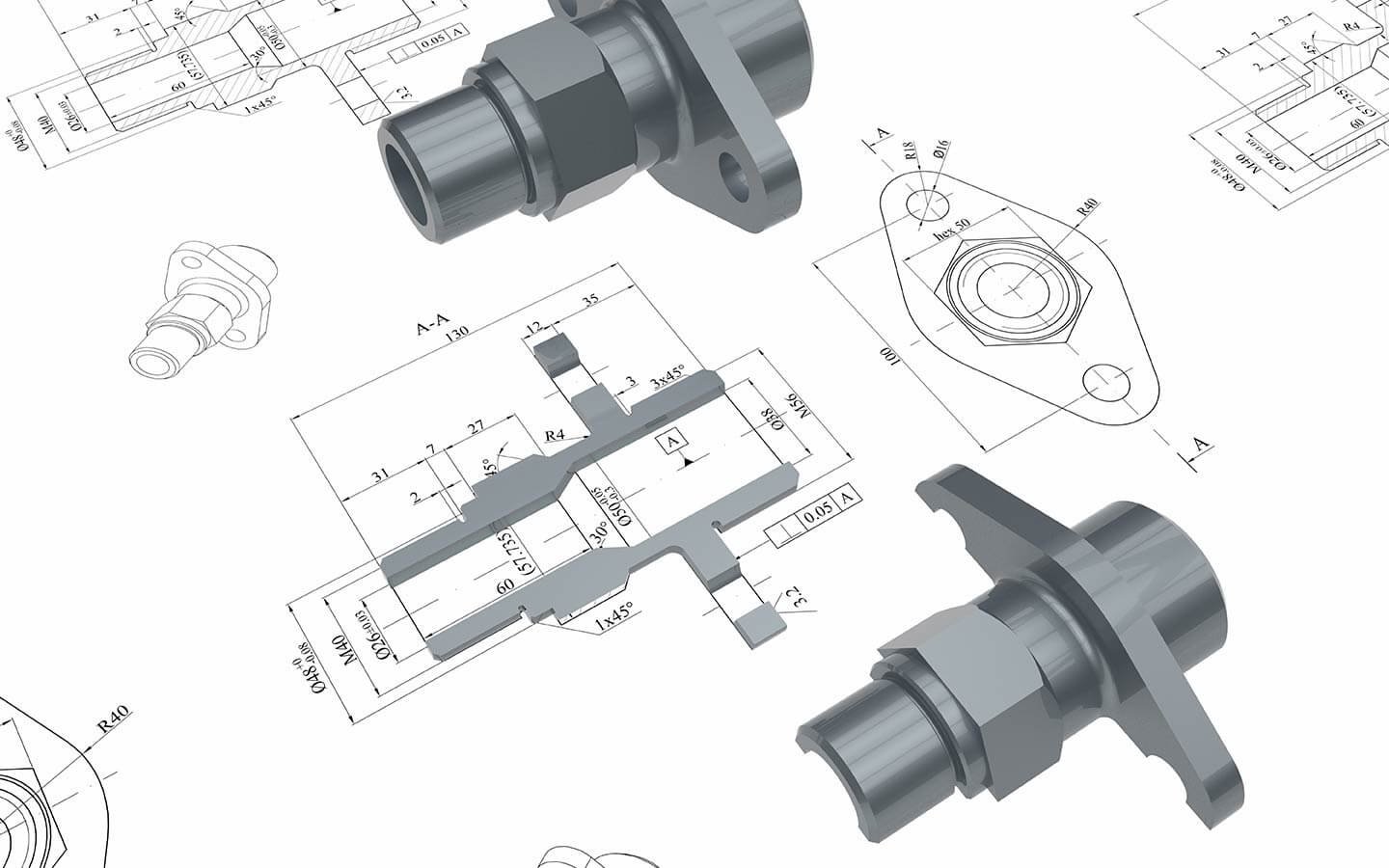

SolidWorks offers easy to use design validation tools that offer you the power to check your designs before you build them - through an equivalent interface you already know so well.

By simulating real-world conditions in 3D, you can gain insight into the performance of your designs, reduce the number of physical prototypes and optimize product performance faster for less money.

Introduction to Solidworks

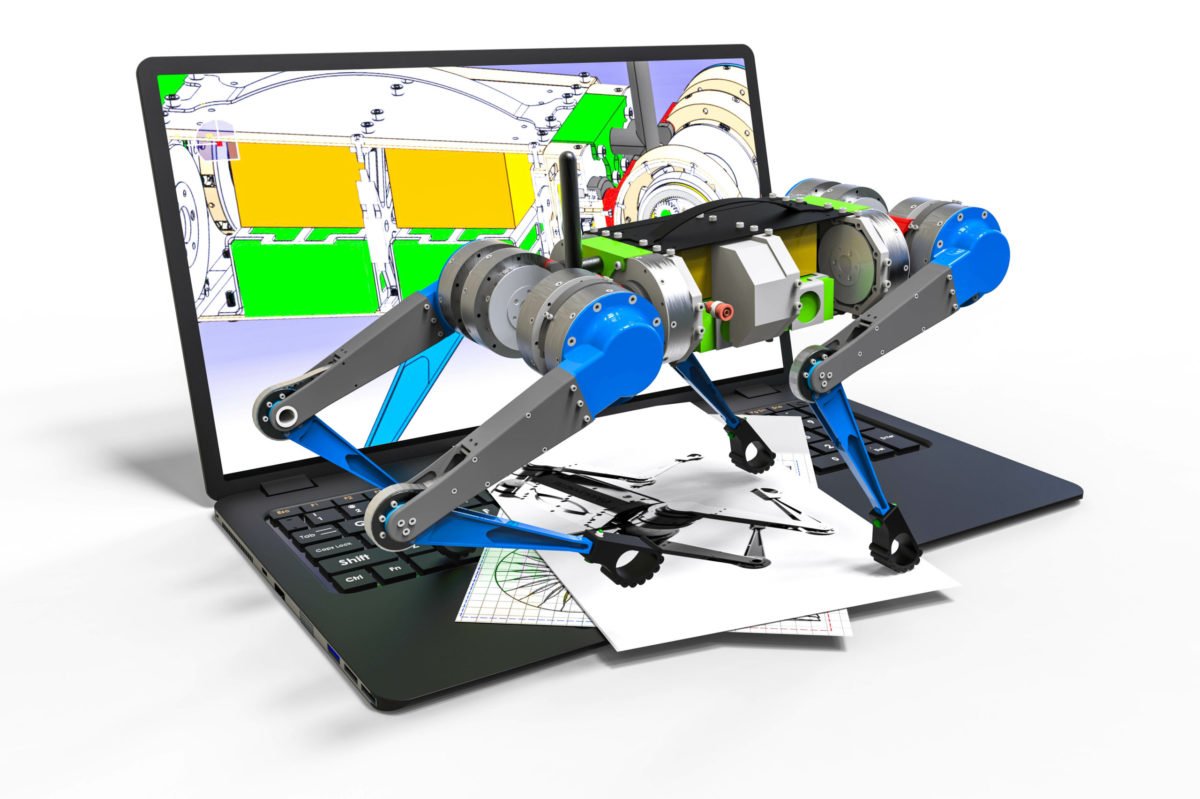

Solidworks, a solid modeling CAD and computer-aided engineering program, is one among the foremost popular software options for mechatronics engineers.

Solidworks is employed to develop mechatronics systems from starting to end. At the initial stage, the software is employed for planning, visual ideation, modeling, feasibility assessment, prototyping, and project management.

The software is then used for design and building of mechanical, electrical, and software elements. Finally, the software are often used for management, including device management, analytics, data automation, and cloud services.

Solidworks core and cavity tools allow for auto generation of parting lines, draft angles and other such features to enable design users to create accurate mould products. Moulds can be created directly from core and cavity geometry within a model and set to industry standards.

Enhance of this digital,grand model?

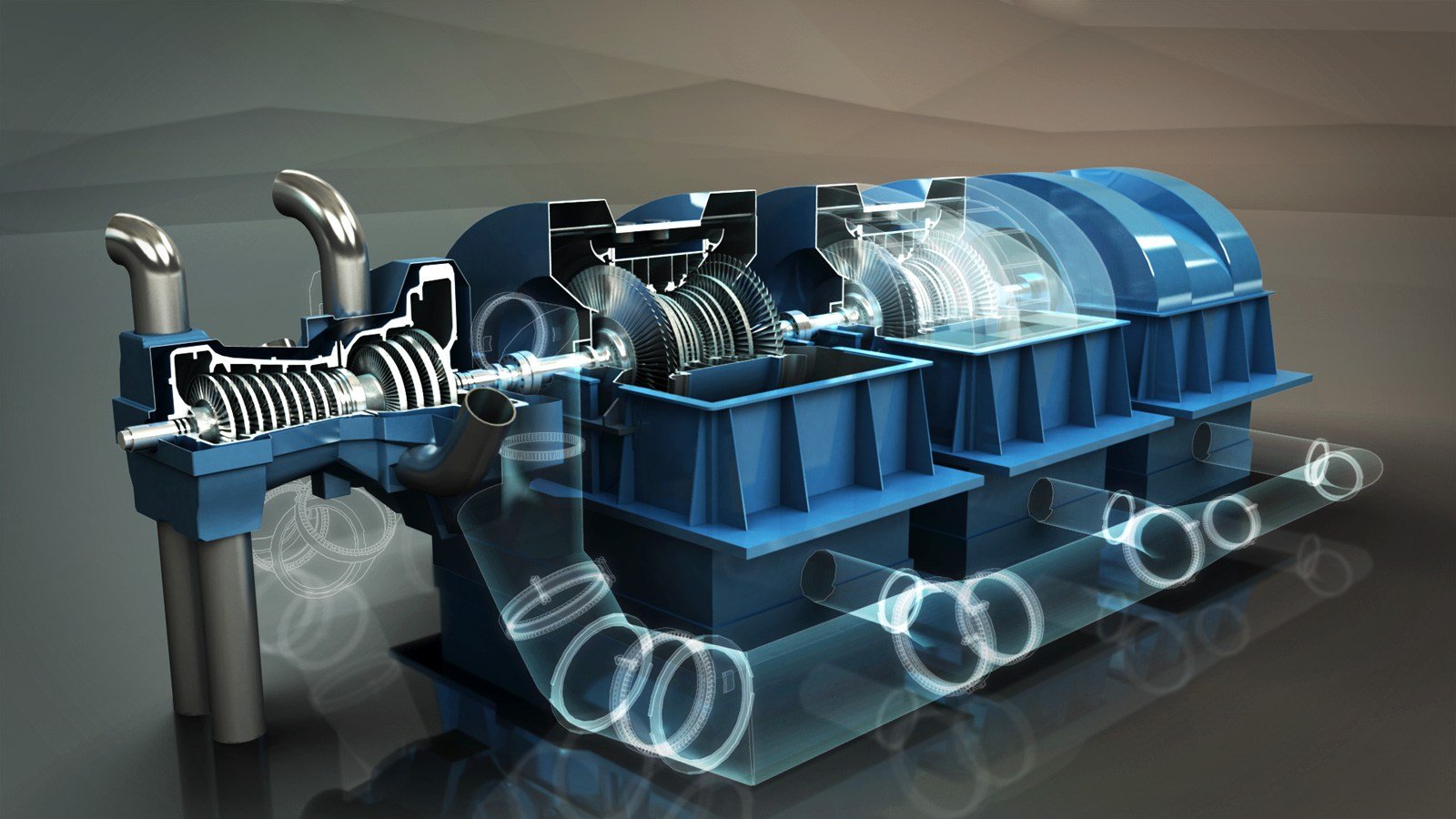

It will be built, of course. Solidworks turned to Dimensional Innovations, a longtime customer, to create a scale model of the space station. Dimensional Innovations is an experienced design, build, and tech firm known for creating immersive experiences for clients like Disney, Google, Home Depot, Audi, the Minnesota Vikings, and much more. Solidworks provided Dimensional Innovations with the full-sized space platform model, and that they scaled it right down to 2 meters in order that they could start building.

Fabricating the model may be a complex endeavor. Dimensional Innovations has turned to Solidworks CAD to assist with hardware and production drawings, using the complete suite of SOLIDWORKS tools to bring the space platform to life. The digitally designed details The Biggest Challenge participants worked on won't be sacrificed with the scaled down model.

Dimensional Innovations is using many various techniques to make the real-world model, like metal working, CNC cutting, high-end 3D printing, electronics, lighting, special paints and graphics, and more. A lot of effort and expertise goes into it, and both SOLIDWORKS and Dimensional Innovations are excited to ascertain the ultimate product.

Start with the Solidworks

So that is it! If you follow this outline, you will have all of the tools you need to start modeling like a champ. Remember that you are only limited by your own creativity, so have fun and continue to grow.

Boost Productivity with Solidworks tools

Become a SolidWorks Professional Designer

Earn Solidworks Certifications

Solidworks Career

Solid works Designers earning……

|

Junior |

$22,000 |

|

Average |

$70,000 |

|

Senior |

$164,000 |

Why Choose Career in Solidworks ?

Solidworks shaping the future of Design & Manufacturing.

Solidworks products are easy to learn and use, and work together to help you design products better, faster, and more cost-effectively. The SolidWorks focus on ease-of-use allows more engineers, designers and other technology professionals than ever before to take advantage of 3D in bringing their designs to life.

Design engineers and manufacturing have a history of poor or strained relationships. The lack of being on the same page can hurt productivity resulting in higher product costs. The 3DEXPERIENCE platform enables you to create project Communities where you can securely invite everyone on the product development project including customers and suppliers.

Conclusion:

After completing the SolidWorks course, one can be eligible for a good career opportunity. SolidWorks opens up doors to jobs in drafting, engineering, and design. After completing the SolidWorks course, you can also pursue UG-NX, Ansys, Inventor, PTC Creo & Solid Edge training courses.

Thank you for taking the time to read this blog.

Copyright Bitonlinelearn © 2021. All Rights Reserved | Design and Developed By BITINFOTECH